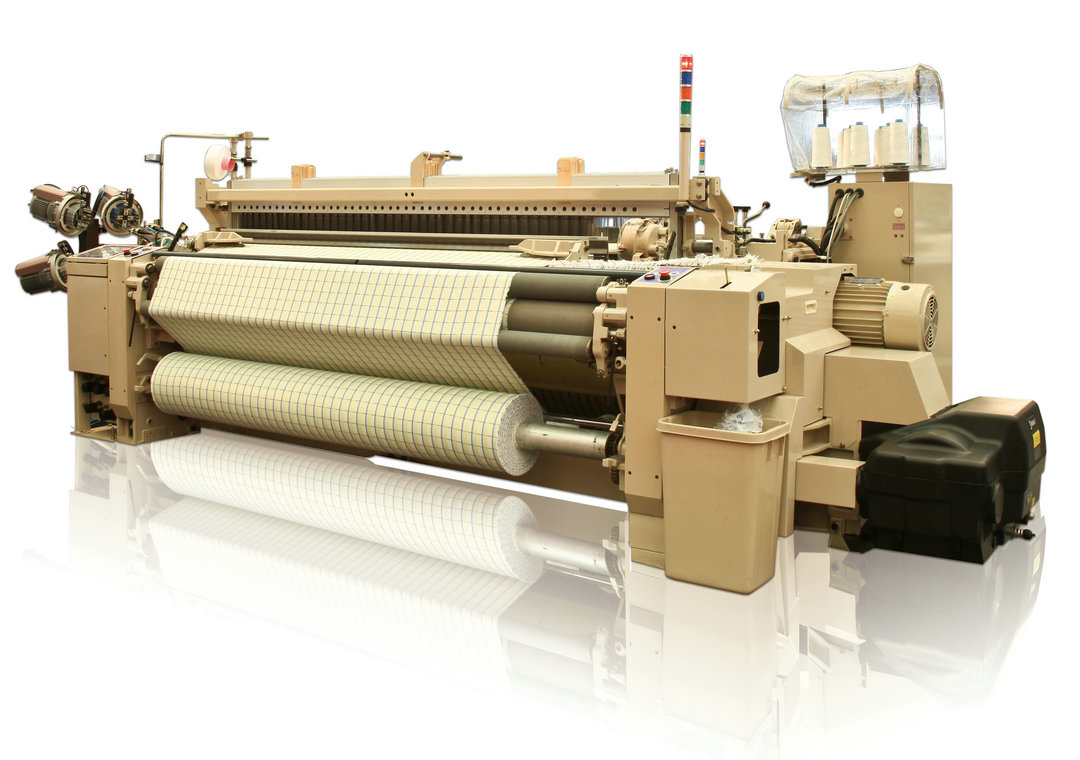

The ZAX-GS is provided with diversified equipment to weave various fabrics. In the fields of multi-colored, wide, and value-added fabrics, the ZAX-GS excellently weaves a wide range of fabrics from general apparel fabrics to denim, worsted fabric, and filament fabric.

ZAX-GS Air Jet Loom

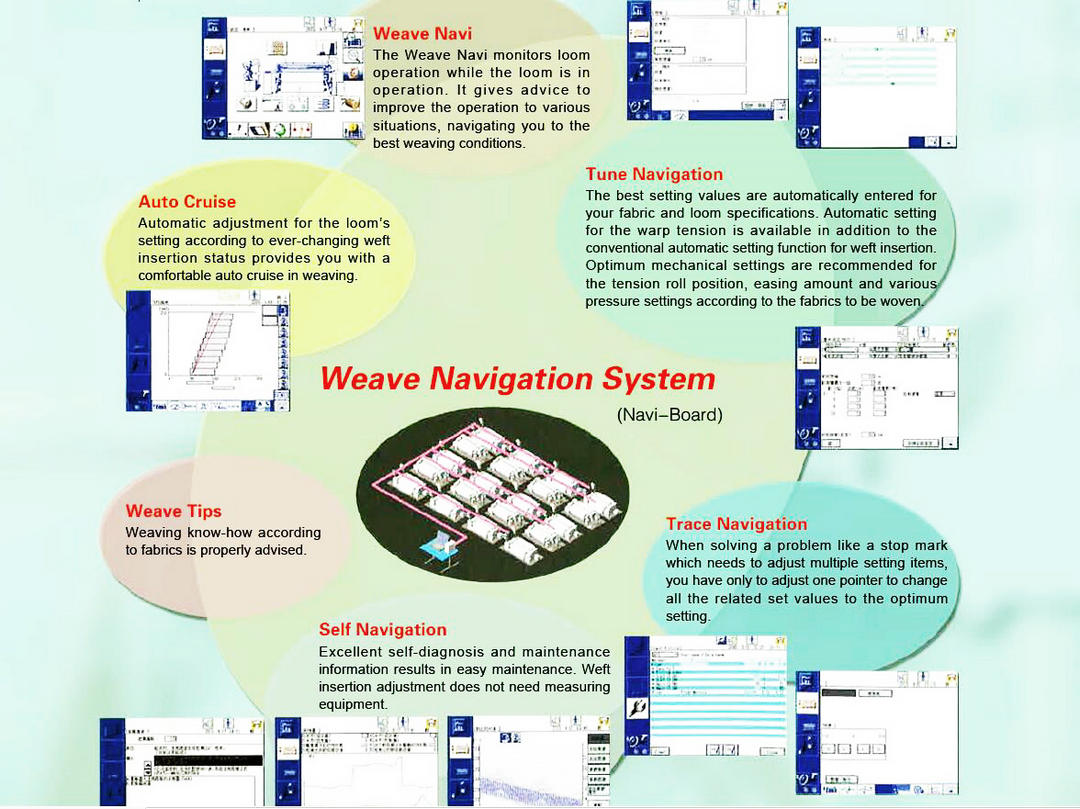

Weave Navigation System

The ZAX-GS expands and enhances automatic setting functions for more detailed and easier operation. Enter a minimum number of items. Conditions to control weaving are set automatically, and our recommended mechanical values are shown. In the operation of the loom can also monitor the condition and provide appropriate suggestions according to the need, navigate loom into optimum working state.

Supreme weft insertion system realizes ultra-high speed operation while saving energy

FDP-A III Free Drum Pooling System

The ZAX-GS entirely adopts this new FDP-A III Free Drum Pooling System in response to the demands for faster operation and wider applicable range of wefts. The advancing reel system is standard and separates weft yarns positively.

First-pick control

The loom speed for the first pick is slower than the specified, so problems such as long pick or tip trouble may occur. The ZAX-N controls filling insertion timing at the first pick by computer for trouble-free start-up to enhance the stability.

Frame structure for ultra-high speed

The robust frame structure, mainly composed of a strong box frame on both sides and beams, has less vibration and is durable enough to weave heavy fabrics at ultra-high speed. The intermediate rocking supporters are standard equipment. They ensure smooth and powerful beating even at ultra-high speed,

promising excellent quality for high density fabric.

ZAX-GS-230-6N Air Jet Loom

The air passage from the electromagnetic valves to the sub-nozzle is minimized by positioning electromagnetic valves with built- in manifolds directly on the front top stay, which is integrated with the air tank. The response at high-speed is elevated, while air consumption is reduced.

Energy Savings

The electromagnetic valves with built- in manifolds have excellent response and produce sharp jetting. The valve stabilizes pressure pulses to ensure stable filling insertion at high speed.

Driving-Rush start motor

The rush start system can delivers highpower torque at starting, enabling increased beating power for first pick, eliminating stop marks, and contributing to high quality production.

ZAX-GS-360-4N Air Jet Loom

Auxiliary main nozzle

By combining an auxiliary main nozzle and the main nozzle, filling is accelerated at low pressure to prevent yarn damage. Even at high speed weaving or extra-wide weaving which may give a load to fillings, it realizes stable filling insertion.The standard auxiliary main nozzle works with the main nozzle.

Besides this, an independently-controlled nozzle to set air jet timing at-will is available.

PSS Programmable Start

Blank start control

This system enables the loom to re-start only by operating the shedding and beating motions, not by inserting the same number of picks as those for reversing the loom. Thus, fabric distortion at the cloth fell is compensated, and such defects as cracks and thin places are prevented.This is very effective especially for weaving at high-speeds as well as weaving thin fabrics.

One-pick insertion start

After repairing a defective pick, fillings are inserted, and the loom is started. By decreasing blank pick beating during forward or reverse rotation, the fabric at the cloth fell can be kept well-balanced. Thus, corrugation marks are prevented.

QIS Quick Insertion Start

The QIS is a re-starting system to prevent stop marks generated by blank beating during reverse rotation in the process of repairing defective pick or warp.

ZAX-GS-190-2N Air Jet Loom

Electronic Let-Off (ELO)for constant warp tension

The reinforced structure, the large-diameter beam gear, and the positive easing driving shaft built in an oil bath ensure good performance even for high-density fabrics at high speed. A large beam flange (up to 1,100mm) can be selected without sacrificing operation ability. (No raising-up is necessary for a flange up to 914mm.)

No cloth fell adjustment necessary

Furthermore, the ELO computer controls warp stretch in accordance with the duration or the cause of stoppage. The kickback function to move let-off beams backward and fell control places the cloth fell in the optimum position. In this way, stop marks are eliminated for the highest quality weaving.

ETU Electronic Take-Up

An AC servo motor is used for the take-up section. Computer controlled, it rotates fullysynchronously

with the loom to control pick densities. The pick densities can be entered from the Navi-Board. No change gears are required. Combined with the ELO, gaiting works are easy.

Soft filling insertion at high speed

A 4-link beating motion that works excellently at ultra-high speed and a short connecting rod are used for standard looms. A 6-link beating motion with more time allowance for filling insertion is used for wider looms, thus achieving more stable filling insertion.

Independent shedding motion for the catch cord

The catch cord shedding is independent from the heald frames. Because all the heald frames can be used for fabric construction, complicated fabric construction is possible. High speed operation can be achieved while saving energy.

Balloon breaker

The balloon breaker makes the filling balloon small to reduce release tension and filling insertion resistance. It is required to operate the loom stably with weak filling.

中文

中文