This machine is applied to coiling sliver formed by card uniformly into sliver can for further processing in draw frame. When the sliver length reaches to the setting value, nobody handling can be realized to break slivers and change cans automatically and go on the next process.

The main driving of coiler is realized either by doffer motor in card via synchronous belt or by individual motor; it adopts small coiling; Disk frame adopts advanced calender rolls and automatic broken-≠tend device; Can-changer adopts carriage driven by cylinder and pulley system for realizing linear can-changing.

Adopting linear double-can auto-changing and saving space; when driving individually, it is more flexible to put position. Full-blown auto-broken-end device is adopted with stable motion and high success rate of end breaking.

Can-changing device with carriage driven by cylinder and pulley system is adopted with simple structure and high reliability.

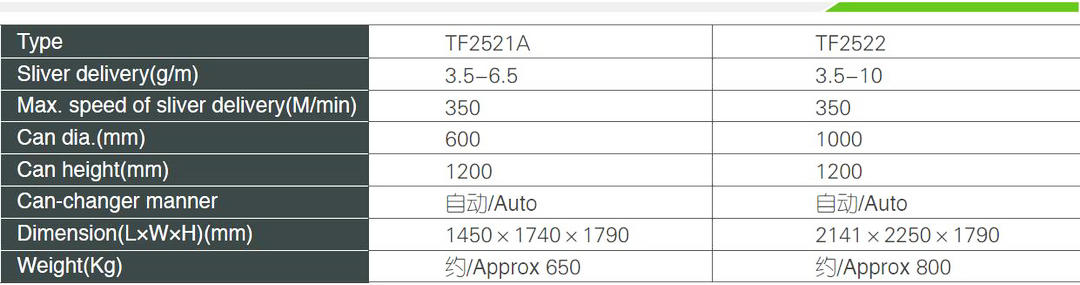

MAIN TECHNICAL SPECIFICATION

中文

中文