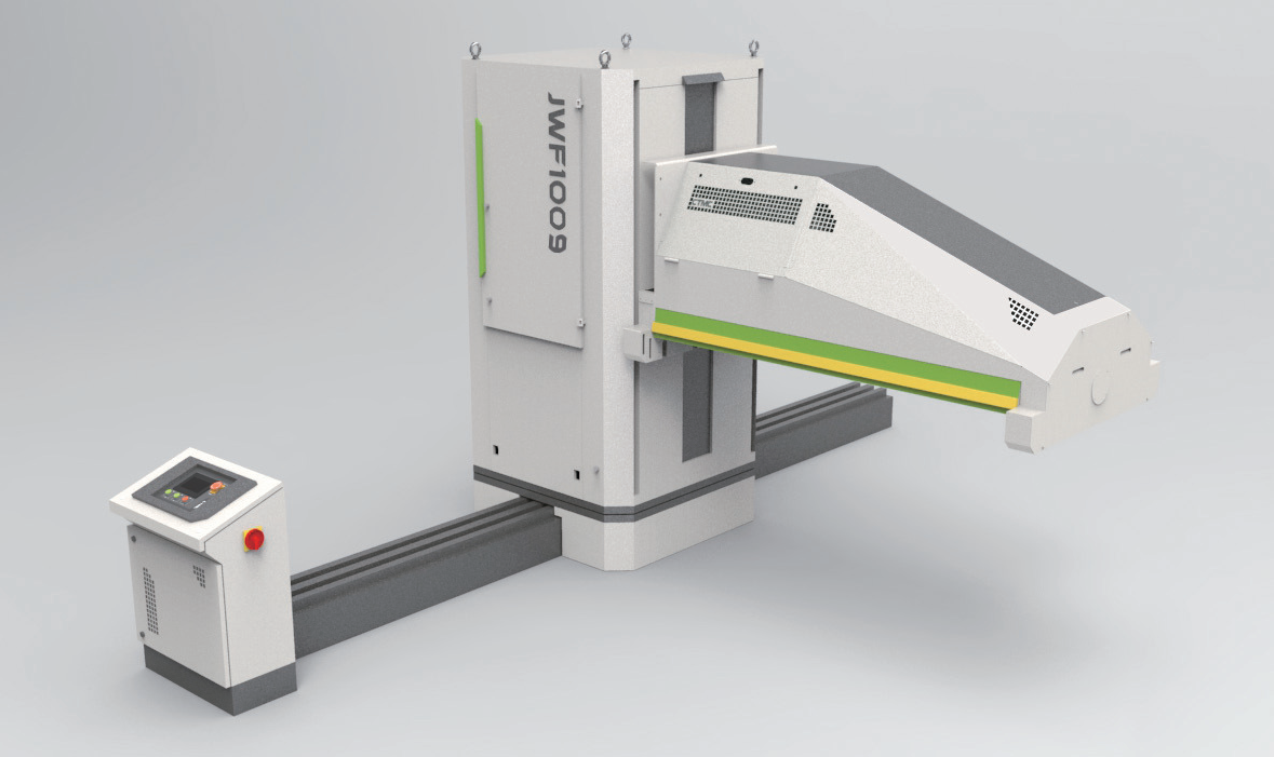

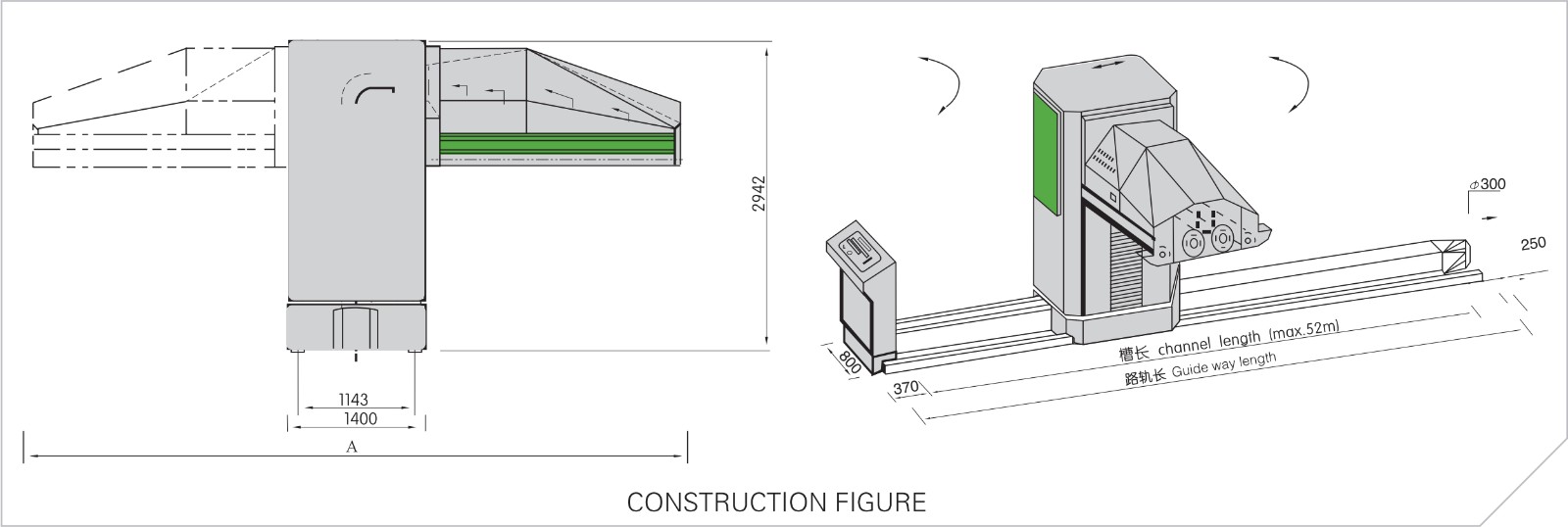

JWF1009 series bale plucker, as the first process of the blowing-carding line, is applicable to process various kinds of cotton, chemical fiber and viscose fiber shorter than 76mm. The pluck arm, equipped with two beaters, goes up and down and can revolve 180°. The pluck arm moves back and forth to pluck the material bales. The material plucked is sucked into the next process by air through the transport duct.

On the basis of inheriting the mature technology of JWF1009, the key parts affecting production of JWF1011 such as plucking arm, suction chamber, beater, grid, cotton compressing roller, suction slot etc. have been designed to meet a higher production target of 2000kg/h.

Technical Features (JWF1009):

The pluck arm is equipped with balance device to ensure stability & safety during goes up and down.

Auto stop function when bales fall.

Bales can be placed in both sides of machine. The machine can pluck 1 to 3 groups of bales in different height and density, meeting the demands of collecting various kinds of yarn at the same time.

Tower can revolve 180°.

The plucking arm is equiped with two plucking rollers and two detecting rollers.

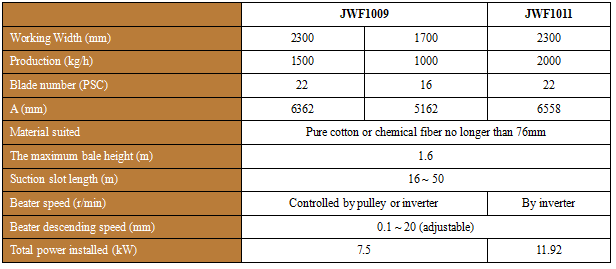

There are 16 plucking knives and 96 tips on JWF1009-170, and 22 plucking knives and 132 tips on JWF1009. While the plucking roller revolves, it makes even distributed plucking line. The position of the knife tips and flaps can be adjusted according to various requirements.

Technical Features (JWF1011):

Increased number of plucking knives for finer plucking.

The beater is driven by double-motors independently to meet a production of 2000kg/h.

Enlarged distance between beaters reduces the interaction of air current produced by beater when rotating in high speed, makes smooth transfer of cotton.

Cotton compressing roller is welded by star-shape steel disc and driven by chain motor to track tower motion, favorable of cotton tuft plucking.

Profile of suction chamber is optimized, favorable of air suction volume even distribution and increasing tuft transfer efficiency.

Enlarged suction slot area realizes high efficiency of cotton transportation.

Flexible action, reliable precision, high automation and intellectualization,ensure convenient integrated control of blow-carding system.

Grid height adjustment function.

Meet the technological requirement of two lines / three types of material in a single machine.

Specifications:

中文

中文