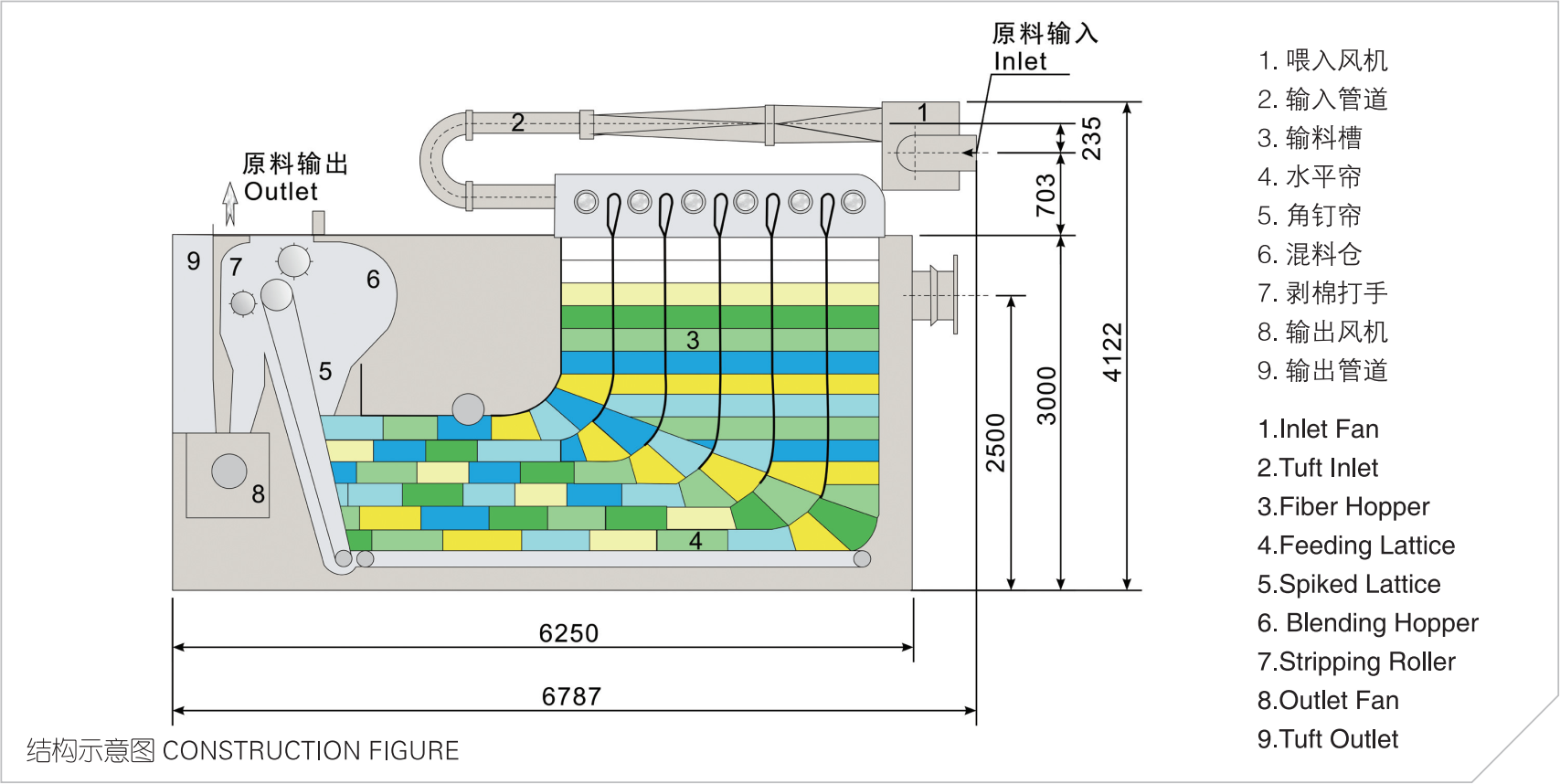

The machine is used for blending cotton, chemical fiber or blends. After fiber is fed into the machine the airflow blows it into every hopper evenly to form an airflow blending. The fiber in every hopper is conveyed in a 90° turn, achieving the second-round blending due to the distance difference. The excessive fiber is thrown into the blending room to attain fine mixture.

Technical Features:

l The tripartite blending ensures the uniform mixing of the material.

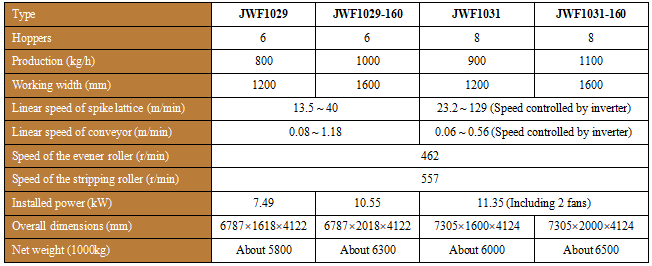

l The structure of six or eight hoppers makes the mixing evener and storage capacity bigger.

l Cotton transportation by the spiked lattice is controlled by the intellectual PID, ensuring the even, stable and continuous cotton supply.

l The speed of the feeding lattice is controlled by the inverter, favorable for controlling the continuous feeding of the system.

l The whole machine is intellectually started and operated. The entrance fan is controlled by the machine itself, favorable for energy conservation.

l The pressure in the hoppers is automatically detected, thus adjusting the plucking amount of the plucker.

Specifications:

中文

中文