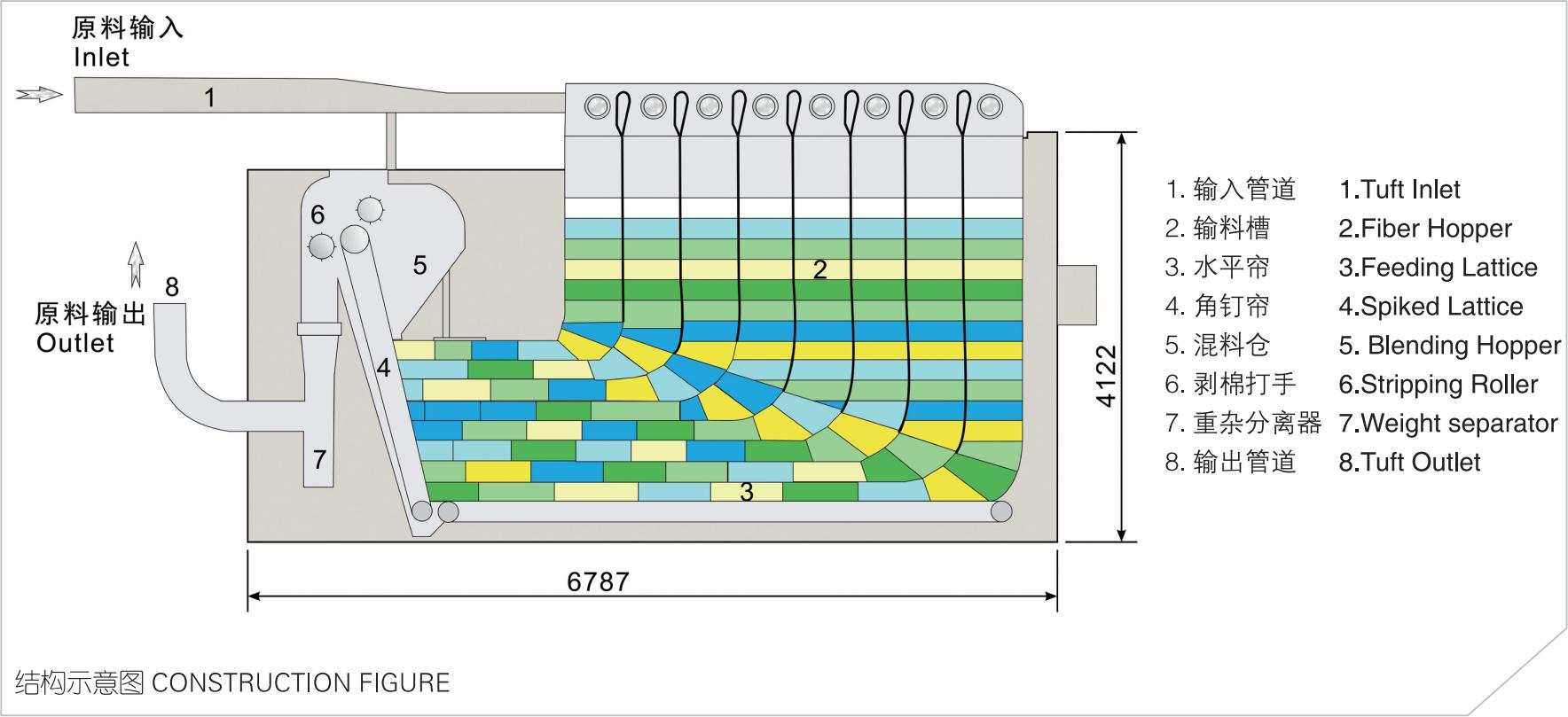

This machine is mainly used for mixing in "plucking, opening, mixing, scotching" process in blow-room. Whose function is to mix material evenly, to make the components with different ingredients contained in material in unit weight equal and eliminate yarn chromatic difference and tenacity irregularity due to uneven mixing. Meanwhile this machine is cotton deposit equipment in blow-room, whose big cotton storage is favorable of continuous and stable cotton supply to followed machine and previous machine stop in short time for handling each fault.

Technical Features:

8 bins with 400-450kg/h cotton storage can mix cotton more full, favorable of stable cotton supply to the followed machine.

Linear feed with little current resistance ensures more smooth feed.

Cotton entrance duct is fit with cotton evening distributing unit, favorable of even cotton feed in transverse direction.

Strengthened triple-mixing effects realizes even material mixing.

The weight separator designed in the cotton exit is favorable of excluding big trash or tube hidden in cotton cluster.

Speed of spiker lattice and belt is controlled inverter favorable of uniform, stable and uninterrupted cotton supply.

Pressure inside bin is automatically detected and cotton supply from plucker is smart controlled and adjusted.

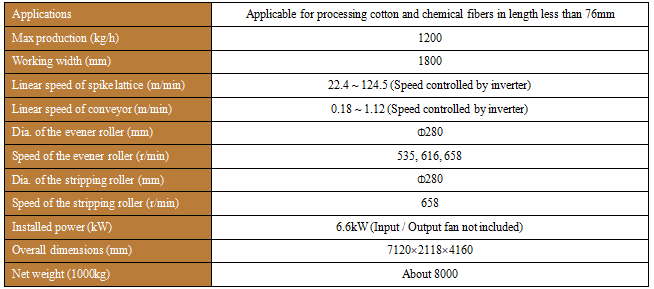

Specifications:

中文

中文