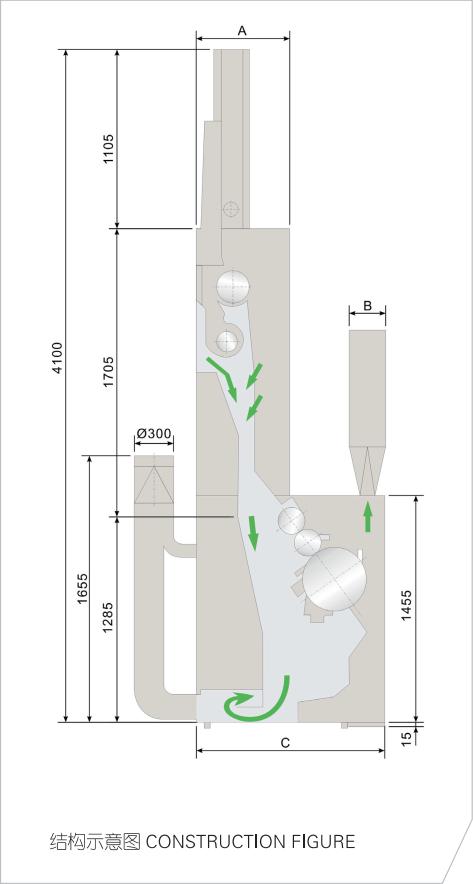

JWF1117 Master cleaner and FA179 chute feeder are used as a group to process various kinds of raw cotton and wool noil. After initial opening, the fiber is further carded by the clothing into single fiber. Impurities are removed from fibers through the automatic suction system. Fibers are sent to the next process through the transporting channel. The material processed by FA116 master cleaner is basically clean and fully opened.

Technical Features:

It has high cleaning efficiency, with low fiber damage.

The metal detecting device and the over-thickness protection measure avoid the possible damages of the wire.

Two feeding rollers and the big carding roller are controlled by the inverter.

It is equipped with the protection device.

Pressure needed inside the transporting channel is automatically detected in three different positions Once it is abnormal, the machine stops automatically.

Impurities are continuously sucked into the filtering chamber.

The covers of these three rollers can be opened for easy maintenance.

These three rollers are clothed with special metallic wire.

It is controlled by the PLC, realizing automatic monitoring.

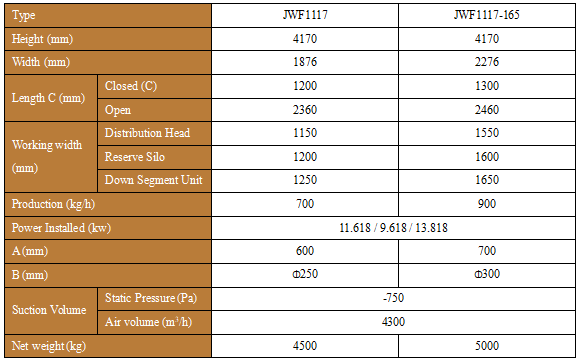

Specifications:

中文

中文