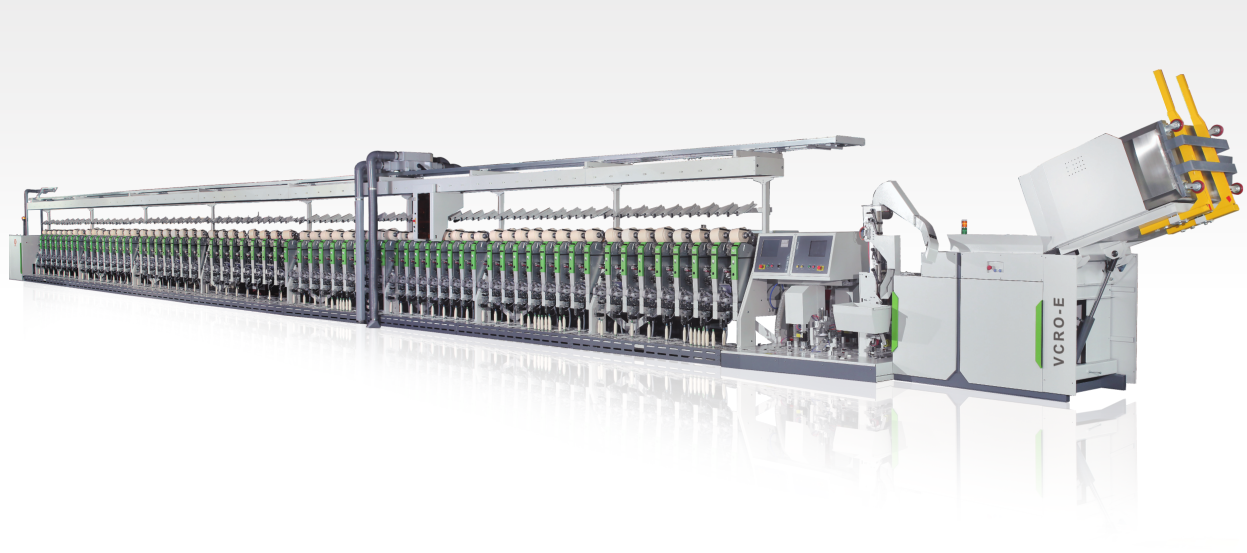

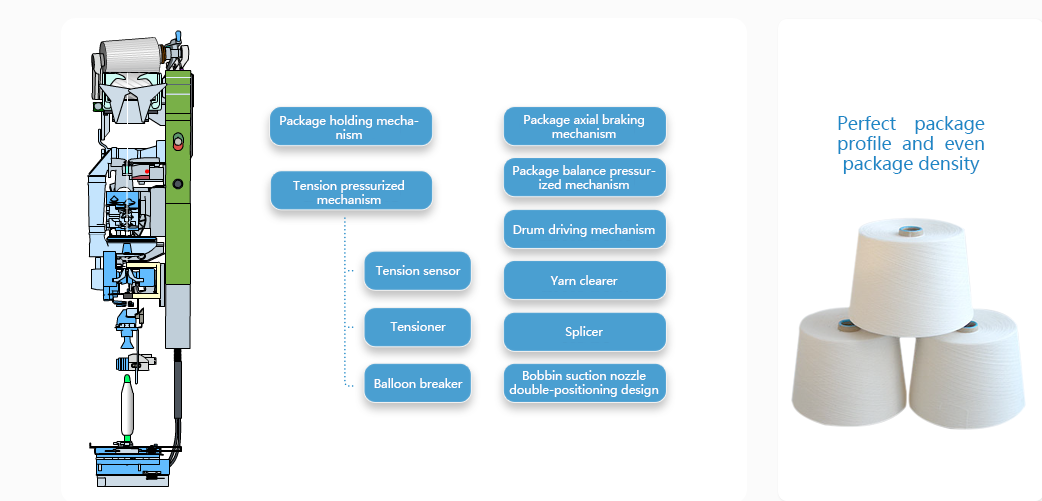

The new generation of auto-winder with tray is developed per latest needs of end users, which is a new model based on SMARO-E auto winder with tray. The new auto-winder can meet the requirements of customers from Ne.6 to the highest count of yarn and it can have 72 spindles in one machine. With several international and national patents for invention are applied for the new machine, it's featured with stable and reliable performance, winding into perfect package, adapting to wide range of various types of yarn and more convenient and easier to be operated.ulla facilisis at seds.

With the tension sensor close loop control, dynamic compensating the yarn tension real-timely. The yarn tension generated could be more constant and benefit to package forming The new bobbin changing mechanism,Driven by a separated motor, can center the bobbin automatically. Whereas, more steady tension is ensured during unwinding of bobbins and to achieve better yarn packages. 798Q joint-air Could be integrated adjusted on control unit of auto-winder. The setting of accurate and consistent parameter improves the consistency in splicing quality among spindles. New aquasplcier with a drop of water valve is optional, which could obtain perfect appearance when splicing special type of yarn.

| Trading Information | |

|---|---|

| Yarn process | Bobbin yarn supply system |

| Auto-doffer | High speed of 60m/min |

| Package yarn | Grid tension sensor |

| Technical Parameter | |

|---|---|

| Yarn supply | 3000bobbins/h |

| Process speed | 50bobbins/min |

| Process max. | 72spindles |

| Splicing place | Set in central |

| Alarm system | Each spindle |

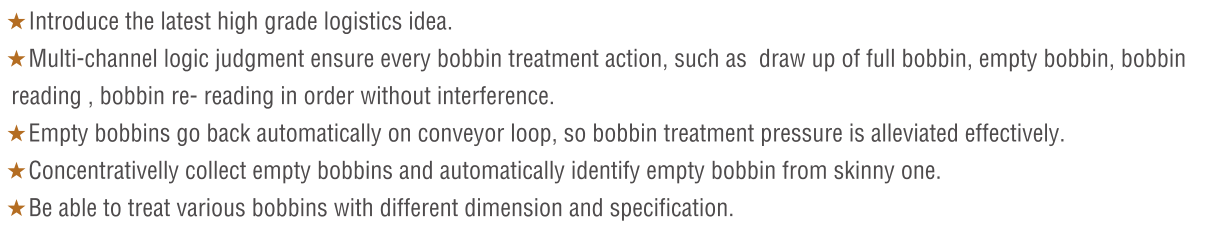

Flexible Bobbin Treatment System

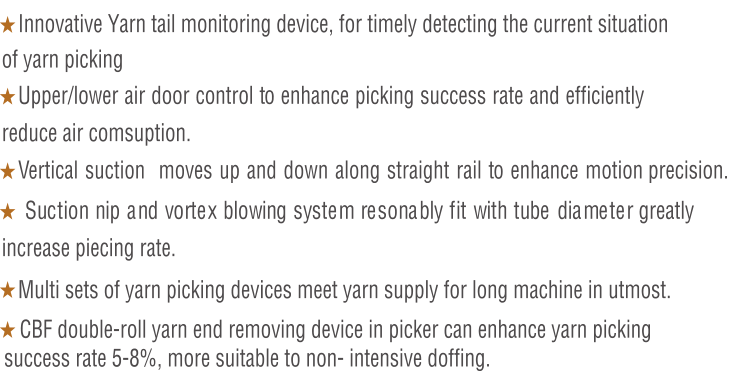

High Quality and High Efficient Piecing Unit

High Efficient, Intellectual New Type of Doffing Carriage

Drum Driven by a Coaxial, Connected Brushless DC motor

Package

Dynamic System

High Quality

Tel-Maintenance

中文

中文