New energy- saving system: Inverter-controlling driving system is adopted to adjust fan speed at real time, close- loop controlling system can stabilize negative air current, so the yarn quality can be guaranteed, and energy can be saved at the same time. Impurities exhausting on both headstock and tailstock.: Trash removal is designated on both headstock and tailstock to minimize the energy consumption and guarantee the yarn quality. Yarn-moving controlled by electronic device can reduce consumption of wear parts, for example top roller, and reduce energy consumption by 5% in comparision with the old type.

New energy- saving system: Inverter-controlling driving system is adopted to adjust fan speed at real time, close- loop controlling system can stabilize negative air current, so the yarn quality can be guaranteed, and energy can be saved at the same time. Impurities exhausting on both headstock and tailstock.: Trash removal is designated on both headstock and tailstock to minimize the energy consumption and guarantee the yarn quality. Yarn-moving controlled by electronic device can reduce consumption of wear parts, for example top roller, and reduce energy consumption by 5% in comparision with the old type.

| Technical Parameters | |

|---|---|

| Head Stock | 2740mm |

| Tail Stock | 3210mm |

| Middle Sector | 2350(It contain 20spindles to 500spindles) |

| Technical Parameters | |

|---|---|

| Machine length | 37.6m(280spindles) |

| 12sector length | 12X2.35m |

| 14sector length | 14X2.35m |

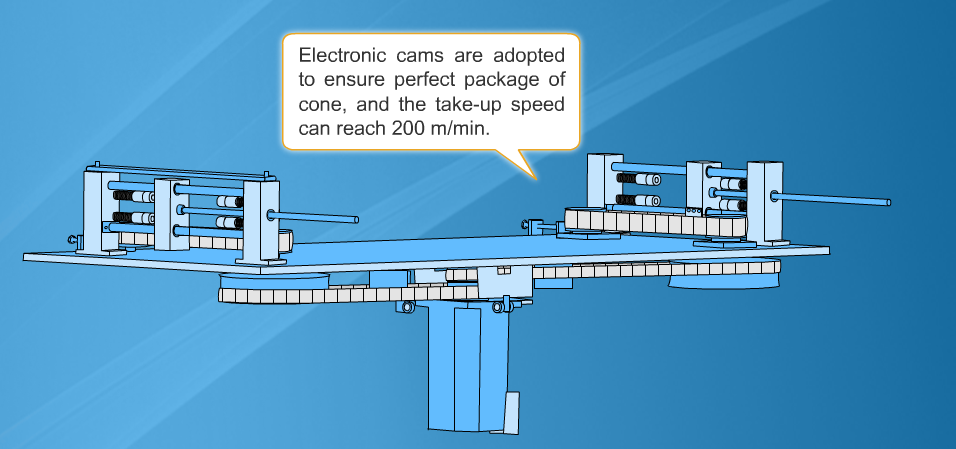

| Electronic cams | 20m/min |

| Hydrolic shock | MMF yarn |

Working Performance

Electronic cams

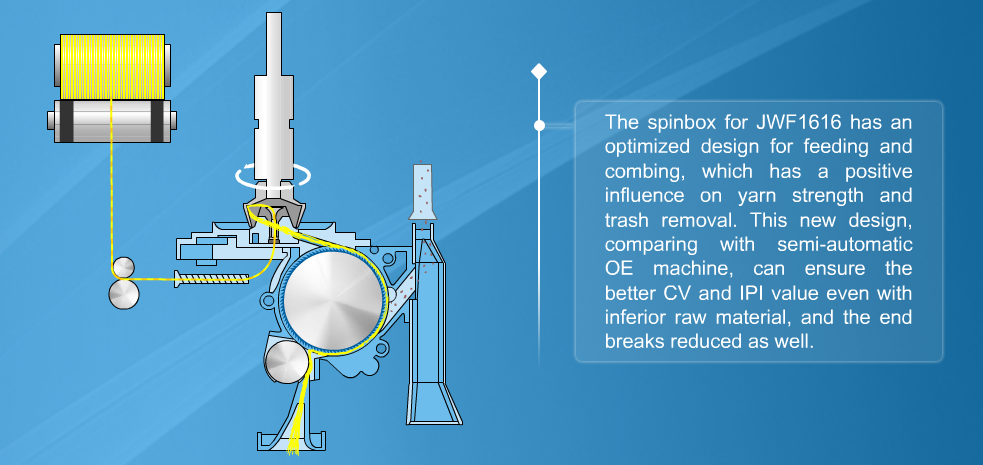

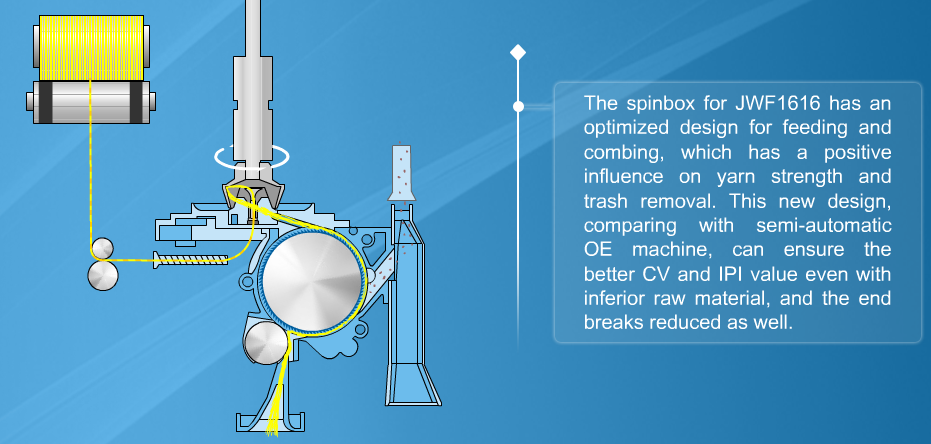

Spinning Unit

中文

中文