The JWF1054 dedusting machine is suitable to process various grades of cotton, it’s designed to remove partial impurities, tiny dust and flocks from the cotton fibers that are opened in previous process. Through the distributor duct, fibers sucked into this machine are evenly ejected onto filter screen plate in high speed for removing impurities, tiny dust and flocks, and then suck them to filter equipment through exhaust pipe.

This machine is installed between cleaner and carding machine, and is suitable for ring spinning and OE spinning, especially for high production blowing-carding process.

Technical Features:

lThe fibers are distributed towards inclined upside by fiber distributor fiber and slides downwards along arc curve line. with more fluent fiber movement and larger production;

lThe inlet of fiber distributor is widened to make fiber distributing more evenly;

lThe perforated plate area is enlarged to increase dust exhaust capacity;

lThe compensation inlet is added at fiber collecting port to avoid blockage;

lInlet fan and outlet fan are all directly connected with inverter.

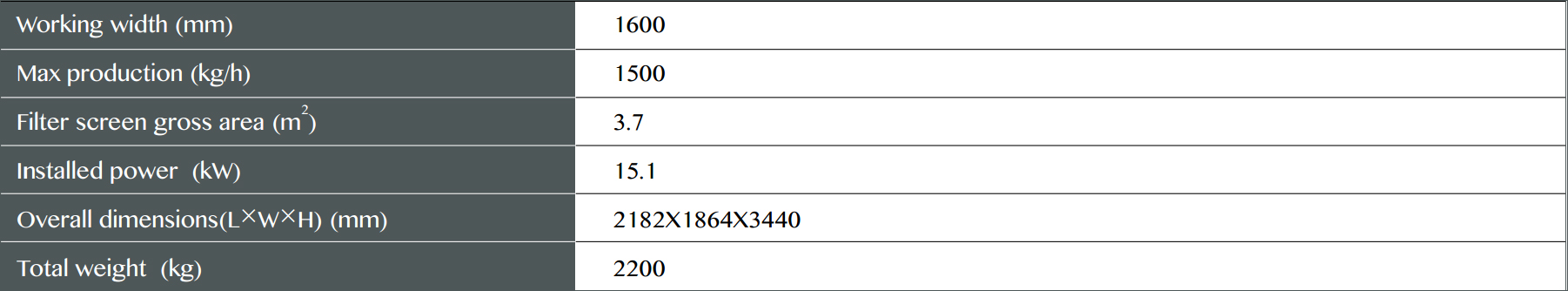

Specifications:

中文

中文