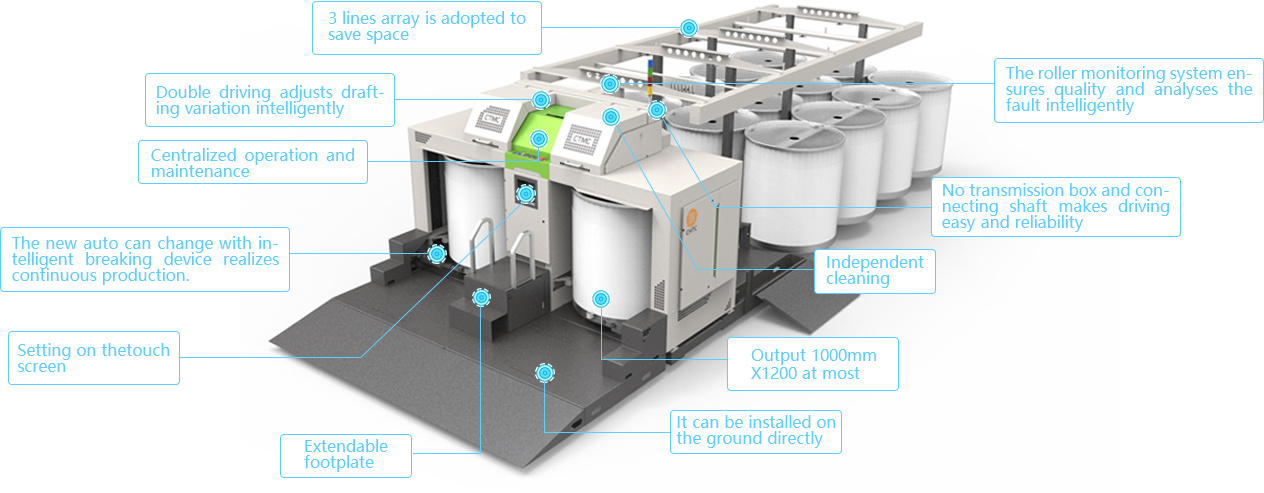

JWF1313 smart draw frame without auto leveller is our new generation. The use of innovative driving form, electronic drafting, output diameter 1000mm, intelligent breaking device, roller monitoring, suction etc. Functions make the machine be able to reduce the cost for the user to create super value benefits.

Low input, high efficiency

☆Production speed can be up to2*800M/min

☆Cost can be reduced by 30%~50% compare with the traditional and import. The length of the arrangement is reduced by more than 2M(3 rows)

☆Two-head delivery diameter of 1 meter draw frame can reduce the average daily workload of 1 hour.

Effective Cleaning Easy Maintenance

☆The main driving adopts maintenance free imported bearings to reduce workload.

☆Main transmission parts are designed to be in the easy reach place when open the cover, reduce maintenance difficulty

☆The roller monitoring system can accurately analyze the drive failure in draft zone and the actual draft multiple output. Reduce maintenance difficulty and laboratory workload.

Simple Operation

☆Double drive control drafting zone, weight adjustment, process transformation can be easy shuttle

☆ The new full-automatic can be changing device with intelligent breaking function can realize continuous production

☆Daily operation are completed in front of the machine,it needs no repeated round operation, saving a lot of time.

☆The touch screen is arranged in the middle of machine. The design conforms to the principle of economics design, and is convenient for data checking and daily operation.

Energy Conservation Environmental Protection

☆The use of energy efficiency standards in line with national energy-saving motor,high power, low energy consumption.

☆The design of the no transmission box is flexible and portable reducing power consumption.

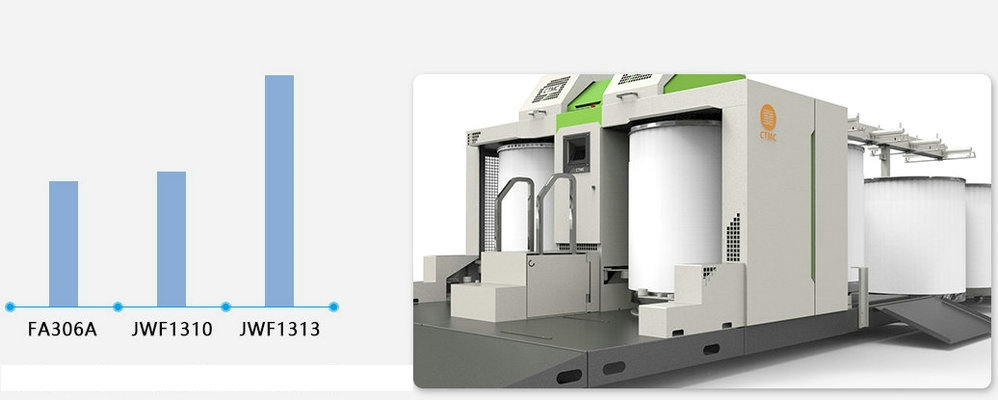

Two-Head Delivery Diameter of 1 Meter Draw Frame

☆This machine has been tested by customers fro long term spinning testing, stable and reliable. Compared to the delivery diameter of 600mm, it has larger capacity reducing the turnover times of 50% in the same output, and it can reduce the average daily workload of 1 hour.

Two Deliveries Large Can Draw Frame in Extremely Easy Operating

The new I-shaped structure with daily operations is completed in front of the machine. This machine can be controlled at the same time in front, shorten the operating time of half, inheriting the traditional practice.

With the patented extendable footplate is in folded state during normal operation. When needing the sliver head shaped or other detailed operation, It can be extended to operating are, bringing the user more safe and convenient operations.

Compared with traditional two heads draw frame, cancel the transmission box, shorten the transmission chain. The transmission of the draft area can be reached the roller by two stages, so that the power consumption , speed, production costs, maintenance and other aspects have great advantages.

Electronic Drafting, Quantitative Adjustment Without Changing Gear

The double motor drive draft area can be draft multiple step less-adjustment, the control precision of the drafting ratio is 0.001, the system response frequency is high; In the production process, whether it is to adjust the weight or change the process, the operator only need to enter the target weight in the touch screen, the system will calculate the draft multiple automatically to adjust, convenient operation.

The application of the double motor drive makes the mechanical transmission simple and efficient. From the main motor to drafting area needs only two transmission, the equipment is flexible, the mechanical failure rate is low, and less spare parts consumption.

Patent Roller Monitoring Function

This machine is equipped with high precision roller speed monitoring, real-time monitoring the drafting area operation state, to realize the draw frame without auto leveller online monitoring function by monitoring drafting multiple, to ensure the delivery stable quantitative in the right feeding.

Sensitive Alarm Stop

In order to ensure the high quality of the delivery slivers, adopting photoelectric sensor or proximity switch in many places has high reliability and long service life which can monitor the running state of the equipment in real time to ensure the quality of the output sliver.

All-New Automatic Can Change Structure

With the patent of all-new automatic can change structure, The change arm can be rotated and folded to reduce the can change distance(area covered) 20%; The design of the mechanism is simple and stable, and it is more stable and easier to maintain the traditional way, and the maintenance period can be extended no more than half a year.

On the touch screen, the broken strip strength can be modified to achieve the function of automatic strip breaking. The adjustment is simple and convenient, without manual maintenance, to adapt to a wide range of varieties,and with the use of automatic can change,realizing continuous production drawing realizing continuous production drawing.

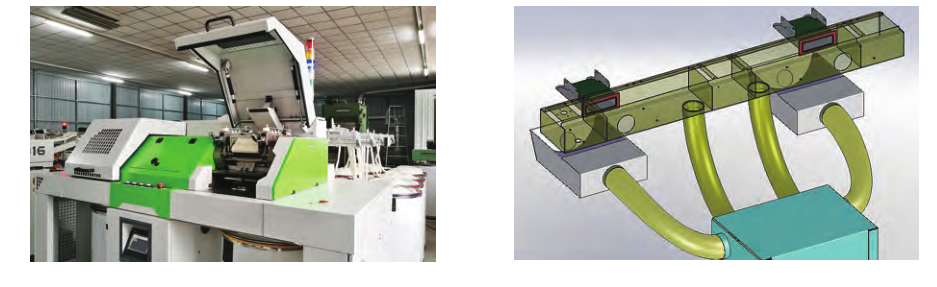

Direct and effective Cleaning System

The left and right areas are completely separated,and the air suction is not disturbed , the air tubes do not interfere with each other. The air volume is adjusted independently, and the air tubes are reached the cleaning points respectively. The cleaning efficiency compared with the rational draw frame improves 50%.

At the same time it is equipped with the under voltage alarm device, when the cotton box flying is too much, the negative pressure is insufficient, suggesting tat needing to clean up immediately, in order to ensure good suction cleaning system.

Steel bar is used fro upper cleaning, effective and stable.

中文

中文