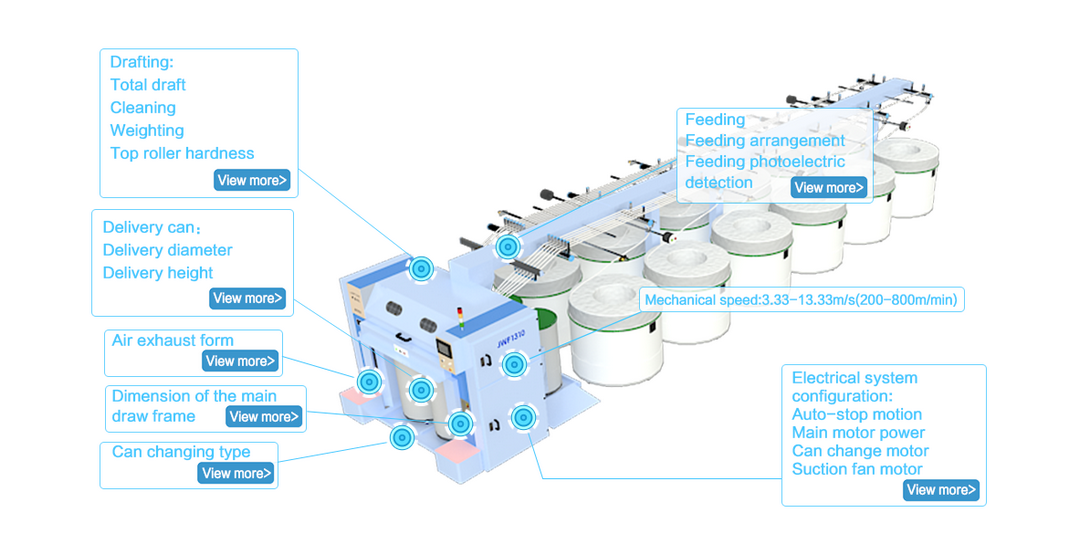

JWF1310 series draw frame is a double delivery high-speed draw frame developed by Jingwei in onder to adapt to the new cotton spinning process devolopment situation,based on the market experience of more tham 30, 000 FA306A drawing frame, and further optimize the development. This machine has inherited the advantages of FA306A series drawing frame, such as stability and reliability. Combining with new process, new technology and new processing means, it improves the high speed adaptability of the main frame and further improves the indexes. It's suitable for pure spinning and blending of cotton, cotton chemical fiber and medium-long chemical fiber under 80mm.

Classic Heritage & Quality Assurance

Cleaning

Independently cleaning tube of both deliveries, equipped with cotton box under voltage alarm device the equipment automatically reminds when cotton box needs to be cleaned. The air tube cover plate is independent which improves the airproof of the air duct improves the air suction effect The design of the air duct part without ribs can effectively improve the negative pressure of the upper air suction and improve the cleaning effect. The under voltoge alarm device is optional.

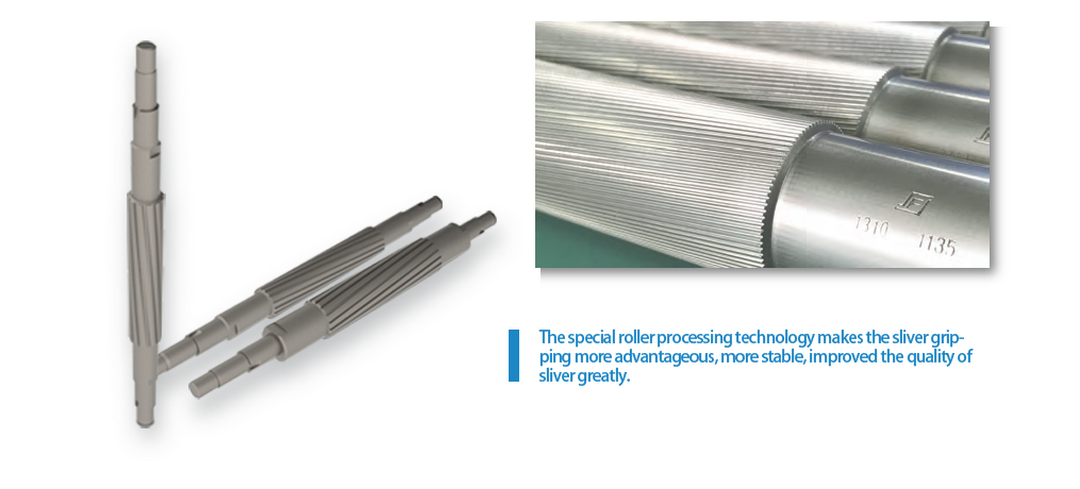

Roller

The tooth shape, angle and processing technology of the bottom roller are further improved, which is more advantageous to the grip of the fiber, more stable, and greatly improves the quality of sliver. Using rollers monitoring technology to monitor the running state of the draft area in real time ensures the quality of the sliver. If the drawing multiple exceeds the set value, it will trigger the alarm stop. (This configuration is optional.)

Driving

The feeding roller can control the tension of sliver uniformly before it enters the drawing zone, centralized speed changing point improves the arrangement of feeding sliver which is propitious to meet the requirements of sliver drawing for high quality feeding.

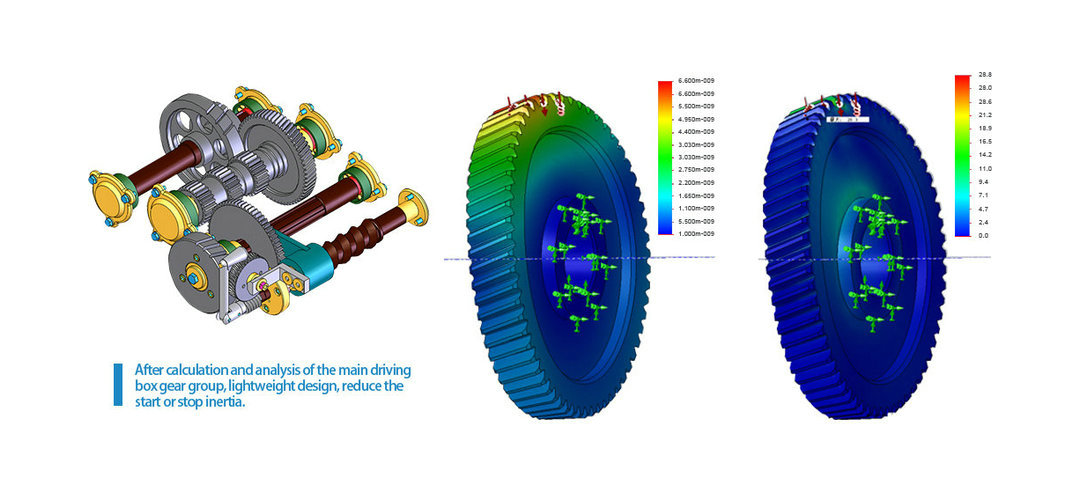

The top and bottom rollers are thorough calculated and the imported high precision needle bearings are selected. The bearing capacity and rotational speed are verified by destructive tests to meet the requirements of high speed and stability.

Through calculation and analysis, the gear set in the main transmission box is lightweight designed to reduce the starting and stopping inertia and increase the transmission efficiency by 5%. Moreover, the oil bath lubrication is sufficient, the transmission is softer and the high speed is more stable.

Delivery in Drafting Area

As the core part of draw frame, this machine extends the type of guide roller with three over three with pressure bars and guide roller which is our rich experience. After nearly 70 years of technical precipitation, the optimal design of the strip angle from the first roller to the trumpet is not obtained by simple physical calculation. The sliver trajectory conforms to the natural motion trajectory, in order to smooth entry into the trumpet to reduce fiber hooks and eliminate fold.

Drafting change

In order to control the fiber better and operate more conveniently, a new generation of integral non-disassembly pressure bar device is used to effectively control the floating fiber. The gap between the pressure bar and the 2nd roller is adjustable in the range of 2mm-3mm.

Automatic Breaking Device

中文

中文