In 2020, the unexpected epidemic has had a serious impact on the overseas market expansion for Jingwei Textile Machinery Co., Ltd. (Jingwei), personnel travels and on-site business promotion activities are severely restricted. To effectively break through the barriers of the epidemic, Jingwei and CTMTC launched a special online promotion meeting with overseas customers and agents on September 1st in Xiayi Hengtian Yong'an New Textile Co., LTD. During this meeting, the presentation in detail showed the latest Jingwei's intelligent cotton spinning equipment adopted by Hengtian Yong'an, which aroused strong response from overseas customers and agents. The atmosphere of the exchange and question-and-answer session was warm.

Participants were impressed by Jingwei's strength in R&D, manufacturing and integrated services, especially surprised by the breakthrough in intelligence, completeness and functionality, and look forward to the further cooperation. This meeting initiated the international online promotion of Jingwei's complete set of cotton spinning equipment, and has become an effective means to actively combat the epidemic.

Xiayi Hengtian Yong'an New Textile Co., LTD is a high-tech company collecting in one the textile, wearhousing, logistics, cotton textiles import and export. Enterprise designs planning the unattended high-end intelligent textile mills with 1 million spindles to produce high quality yarns such as compact yarns and compact siro yarns. Main product includes but not limited to high-end yarns ( up to 220 yarns ) such as high-count fine staple cotton yarn, super fine cotton yarn, etc., and functional blended yarn made by high-end chemical fibers such as modal, Tencel, lyocell, etc.

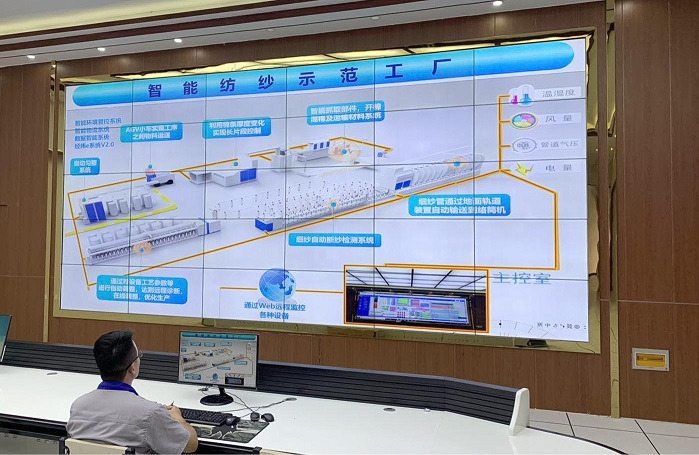

Overall positioning of the project is high-end, the entire process using Jingwei's high-end intelligent equipment, and equipped with whole process intelligence spinning system, including blowing-carding unit, auto-leveler draw frame with automatic can-exchange (big sliver can), tri-automatic comber (automatic tube removing, automatic lap changing and auto-jointing), auto-doffing roving frame, positive lifting full electronic spinning frame, auto-winder, roving-spinning unit, auto-packaging system, Jingwei e-system, Automatic conveyance AGV, etc., which represents the domestic advanced, industry-leading products and technology.

The first phase plans 500,000 spindles divided into four independent mills of 125,000 spindles. At present, 125,000 spindles have reached the designed production capacity and entered into the normal operation. The second mill has completed the setup and commissioning of 60,000 spindles and entered into production, the rest of the equipment is scheduled for setting up in October, and it will reach the designed production capacity at the end of the year. The third and the fourth plant has been capped, and the equipment assembly is scheduled for next year.

The whole process equipment is characterized by high yield, high efficiency, high quality, and energy-saving which can fully meet the customers' demands such as high technical requirements, complex equipment configuration, and various personalized needs. It shows the strength and brand image of Jingwei and set up a new benchmark of intelligent factory construction for the industry.

中文

中文